When collaboration and innovation collide, ‘impossible’ has no place

Written by Paul Rellinger

Shame on those who don’t answer when opportunity knocks.

Those at the helm of three very successful local manufacturers certainly know that.

In fact, they don’t wait for the knock. Their welcome mat in place, their doors are always open to new possibilities that promise mutual benefits for all involved in any resulting collaboration.

Case in point. During the darkest months of the COVID-19 pandemic, Charlotte Products found itself facing a formidable, and potentially disastrous, challenge that was being experienced by manufacturers not just locally but around the globe.

“During COVID, we were in the war room every day,” recalls Charlotte Products CEO Matt Strano.

“We found ourselves in a supply chain crunch. We couldn’t get bottles (for cleaning solution). That’s a huge thing. We’re making a liquid and we can’t bottle it.”

The answer, notes Strano, was literally on the company’s Fisher Drive front step.

“The Ontario government was big into supporting organizations that were dedicated to finding solutions for a stronger supply chain,” says Strano.

“When we found out we had an opportunity to apply for Ontario Together funding, we went to Merit (Precision) – they’re across the street – and said ‘Let’s form a partnership here.’ We’ll see if we can get funding for blow molding machines. They will operate it because that’s their expertise.”

“We bring the bottles over here. Not only does that help us control our supply chain – we control that destiny – but think of the positive environmental impact. We had bottles coming from the United States. That transportation carbon footprint…we don’t have that anymore.”

Matt Strano, Charlotte Products CEO

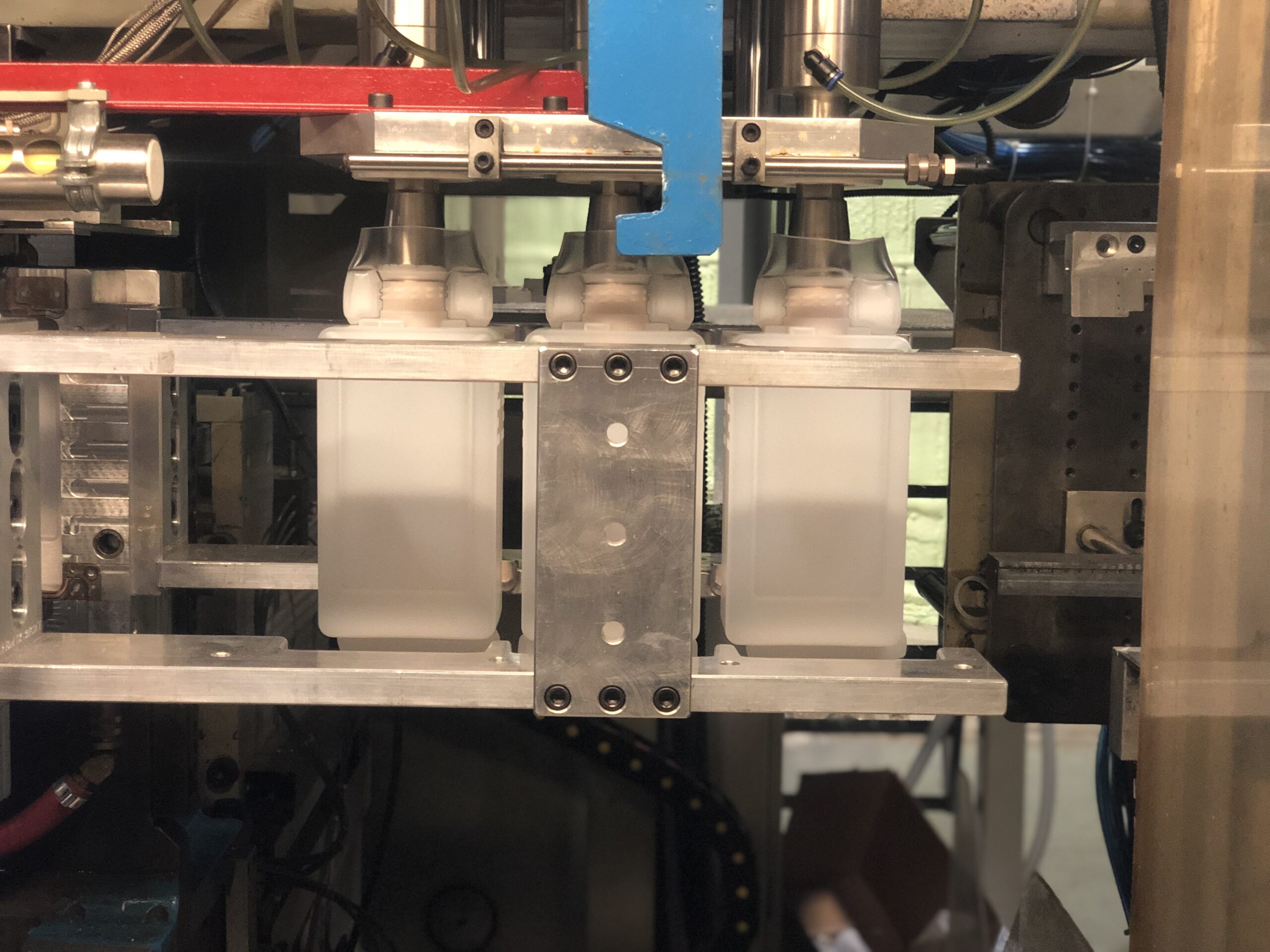

At Merit Precision, vice-president and general manager Dan Bailey explains that the company typically employs an injection molding process for its clients – a list that includes General Motors but also features local companies Savage Arms and Siemens Milltronics. To produce bottles for Charlotte Products, blow molding was a whole new ballgame.

“We ended up buying blow molding machines from a Montreal company and put them in our plant. We put the bottles on skids, close the doors to the trailer, run them across the street and they unload them. The shipping cost is next to nothing. We run two blow molding machines daily and ship bottles every other day to Charlotte (Products).”

Besides supply chain challenges, there was another adverse byproduct of COVID – a serious shortage of alcohol-based hand sanitizer. That product had been coming north from the United States but when COVID hit, the flow was stemmed in a big way. As Strano recalls “There was a gap.” There was also an opportunity.

Enter Kawartha Ethanol. The Havelock manufacturer, which ferments and distills corn for the production of fuel-grade ethanol, was also affected by the pandemic. Plant manager Steve tenDoeschate explains “the margins were very tight” for its core product. That, he says, forced a review of “the most sustainable use of the plant” which, in turn, prompted the decision to convert to “largely a distillery…basically a high-quality alcohol plant. This was not a minor tweak. This was a redesign of our plant.”

At Charlotte Products, which was retrofitted to produce alcohol-based products – disinfectants and wipes – Strano et al entered an agreement with Kawartha Ethanol for the supply required to keep up with the demand for hand sanitizer.

“We’re buying our ethanol from a plant that’s 20 miles away, we’re blow molding the bottle that is part of our hand hygiene program across the street and we’re producing it right here in Peterborough…when you look at the big multinationals, they don’t have that story,” says Strano.

For their part, both tenDoeschate and Bailey say business partnerships such as the one which this triumvirate is reaping benefits from is rooted in keeping the lines of communication – no matter how innocuous – open.

“The principal owner (of Kawartha Ethanol), Darrell Drain, has a relationship with the owner there (Charlotte Products),” notes tenDoeschate.

“They became aware of what we’re doing here and, very early on, they were identified as someone we were going to work with for this new product stream that they took on. A good, reliable local customer is ideal.”

Collaboration-anchored opportunities, adds Bailey, are part and parcel of Merit Precision’s “diverse think…we don’t stay in the box. If there’s an opportunity, what do we need to do? How do we need to change to make the most of this opportunity? As you take those first steps, everything changes.”

Bailey adds there’s another benefit besides the positive effect on the bottom line.

“When you’re working with multiple industries, you get the benefits of best practices from all industries rather than just one,” he says.

Bailey adds collaboration isn’t new but the pandemic forced it to occur more regularly as manufacturers tried to keep their slice of the business pie.

“We initially worked with Harco Enterprises Limited making face shields,” he explains.

“Within the first month of COVID, between us, supplied PRHC with like 2,000 face shields when everybody was scrambling to get them. We also grouped in with Ventra Plastics, trying to pool our resources. We’re all normally competitors but there was a lot of collaboration.”

“There are lots of ways of working deals that can work out for everybody. You can’t draw a line in the sand and say ‘No, we’re just doing this and that’s it.’ Things change and they change quickly. You have to have the systems in place, and the mindset in place that you’re going to change. A lot say ‘This is my wheelhouse. I’m going to stay within it. I don’t want to move out from that.’ The problem with that is you end up with all kinds of shortages and then you’re out of business in a hurry.”

Strano couldn’t agree more.

“It’s a great way to grow Peterborough…everyone coming together to think of innovative ways to form new businesses or grow businesses,” he says.

“If you continue to not innovate or offer better solutions for your customers, you’re going to be replaced. You always have to be on your toes. If you have an entrepreneurial spirit, collaboration will help you get where you want to be.”

Matt Strano, Charlotte Products CEO

When all is said and done, says tenDoeschate, it comes down to relationships.

“It’s no secret that Darrell (Drain) has operated much of his business on a handshake and my understanding is Charlotte (Products) is much the same way,” he says.

“Beyond the business relationship, when you have that level of trust with local producers, it allows you to more confidently expand your business or expand more aggressively than you would if you were uncertain about those relationships.”